What is a modular power supply/power module? What are the product classifications?

Date:2026-02-05 Publisher:BettpowerIn industrial automation and smart manufacturing scenarios, reliable power supply is crucial for stable operation of industrial equipment, and industrial modular power supplies serve as the core safeguard. It is a standardized power conversion device that precisely transforms electricity of varying specifications into stable power required by equipment. Boasting advantages such as compact size, high efficiency, reliability, and ease of integration, it is widely used in industrial control, rail transit, new energy, and medical equipment sectors, earning its reputation as the “energy cornerstone” of the industrial field. Understanding its classifications and characteristics is crucial for selecting suitable products and enhancing equipment stability.

Based on power conversion methods, industrial modular power supplies primarily fall into two categories: AC-DC and DC-DC. While both core functions involve power conversion and voltage stabilization, their applicable scenarios, technical characteristics, and parameters differ significantly. Below, we clarify these distinctions across three key aspects: power range, packaging styles, and specialized models for specific industries.

I. AC-DC Power Modules: The “Power Bridge” Converting AC to DC

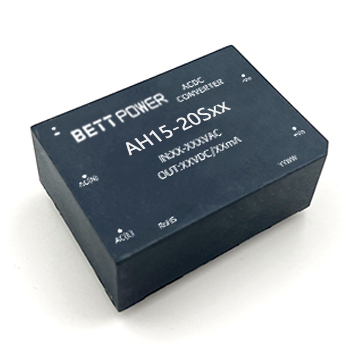

AC-DC power modules act as the “power bridge” connecting mains electricity to industrial DC equipment. Their core function is to convert household or industrial AC 220V/110V mains power into stable DC voltage. They adapt to complex grid environments, offer strong interference resistance, and support a wide range of input voltages. Power coverage spans a wide range: - Low power (≤100W) suits light-load devices like sensors and small control modules; - Medium power (100W-500W) powers core equipment such as PLCs and inverters; - High power (>500W) supports heavy-load applications like industrial welders and rail transit traction systems. Three primary packaging styles exist: - Open-frame modules are compact and suitable for embedded installations; sealed types for direct cabinet mounting, which are widely used; and potted types for harsh environments with high temperatures, humidity, and vibration. Additionally, specialized variants exist for different industries, including medical-grade (ultra-low leakage current), rail transit-grade (EMC-resistant and vibration-tolerant), and explosion-proof-grade (flameproof and intrinsically safe designs).

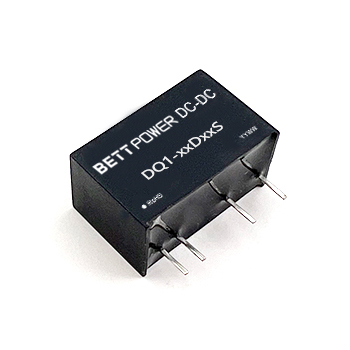

II. DC-DC Power Modules: The “Precision Regulators” of DC Voltage Stabilization

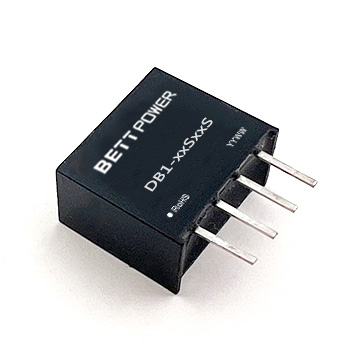

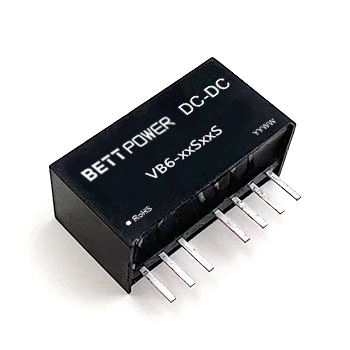

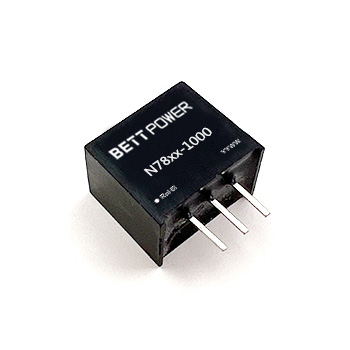

DC-DC power modules function as “precision regulators” for DC voltage, converting one DC voltage level to another (e.g., converting DC 48V to 5V or 3.3V). Their advantages are prominent: high conversion efficiency, accurate output voltage, and low ripple, making them particularly suitable for powering precision circuits. Power ratings primarily target precision loads: Low power (≤10W) is mainstream, suitable for micro-sensors and microcontrollers; Medium power (10W-100W) supports PLC core circuits and communication modules; high power (>100W) is tailored for new energy battery management systems. Packaging emphasizes miniaturization and integration, with three common types: surface-mount types enable automated assembly, suitable for mass production; modular types facilitate installation and replacement, ideal for small-batch custom equipment; DIN-rail types mount directly on industrial rails, simplifying wiring and maintenance. Specialized variants abound, including military-grade models (operating from -55°C to 125°C with radiation resistance and shock tolerance), new energy-specific designs (providing balanced lithium battery power with overcurrent protection), and precision instrument versions (featuring ultra-low ripple).

Conclusion: Precisely Matching Demands, Fortifying Industrial Power Foundations

AC-DC and DC-DC power modules collectively form the core backbone of industrial power supply, precisely meeting diverse application requirements. With the advancement of Industry 4.0, these modules are evolving toward greater efficiency, smaller form factors, and enhanced intelligence—such as remote monitoring and predictive fault alerts—to safeguard smart manufacturing and related fields. Selecting the right power module not only ensures more stable equipment operation but also helps businesses reduce operational and maintenance costs.

Sample

Sample

Tel

Tel

Email

Email

TOP

TOP