Industrial Control Power Supplies: The Heartbeat of Industrial Automation

Date:2025-05-23 Publisher:BettpowerIn today's highly automated industrial world, there exists an indispensable yet often overlooked component. Much like the heart supplies blood to the human body, it continuously delivers stable, reliable power to various automated equipment and systems. This component is the industrial control power supply—the unseen guardian ensuring the smooth operation of industrial control systems.

What is an Industrial Control Power Supply?

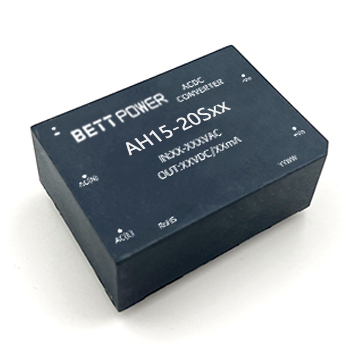

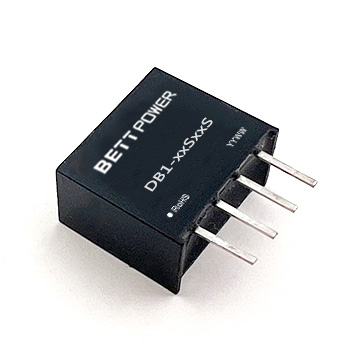

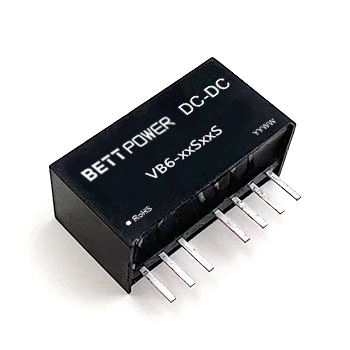

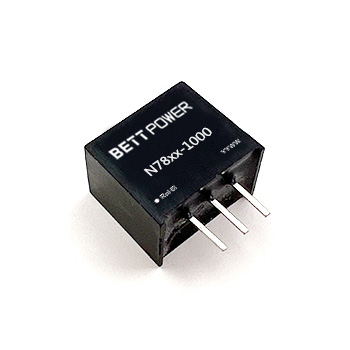

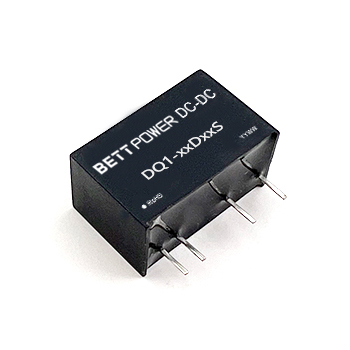

An industrial control power supply is a specialized power conversion device engineered to meet the demanding electrical requirements of industrial environments. It transforms mains power or other input sources into DC or AC electricity suitable for industrial control equipment. Compared to standard commercial power supplies, industrial control power supplies feature wider input voltage ranges, superior noise immunity, and enhanced environmental adaptability, enabling stable operation under harsh conditions such as extreme temperatures, high humidity, and dusty environments.

Core Features of Industrial Power Supplies

— High Stability: Utilizes premium components and advanced circuit design to ensure minimal voltage output fluctuations, preventing equipment downtime or data loss due to power issues.

— Strong Interference Resistance: Complies with EMC (Electromagnetic Compatibility) standards, effectively resisting electromagnetic interference in industrial environments to guarantee stable equipment operation.

— Wide Temperature Range: Operates reliably from -40°C to 70°C or beyond, adapting to extreme conditions including high temperatures, humidity, and dust.

— Long Lifespan and High Reliability: Industrial-grade design delivers extended Mean Time Between Failures (MTBF), reducing maintenance costs.

Industrial Power Supply Applications

— Manufacturing Production Lines: From automotive assembly to electronic component fabrication, industrial power supplies deliver stable electrical support for automated equipment like PLCs (Programmable Logic Controllers), robotic arms, and sensors, ensuring continuous and efficient production processes.

— Smart Warehousing & Logistics: As automated warehouses and intelligent sorting systems proliferate, industrial power supplies energize AGVs (Automated Guided Vehicles), stackers, and information management systems within these high-tech facilities, driving the intelligent evolution of logistics.

— Energy Sector: Whether in wind farms or solar power stations, industrial power supplies are core components ensuring the stable operation of monitoring systems, inverters, and other critical equipment, playing a vital role in enhancing the efficiency of new energy utilization.

— Transportation Infrastructure: In subway systems, railway signaling systems, and airport navigation systems, industrial power supplies guarantee the accuracy and timeliness of signal transmission, safeguarding public transportation safety.

Though less flashy than robots or AI, industrial power supplies serve as the “invisible guardians” within industrial automation systems. From precision production lines in smart factories to critical infrastructure vital to public welfare, their stable operation is indispensable. Selecting a high-performance industrial power supply provides a solid safeguard for both production efficiency and safety!

Sample

Sample

Tel

Tel

Email

Email

TOP

TOP