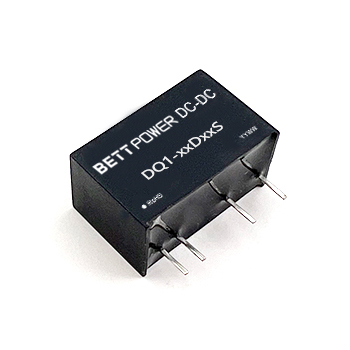

Components Used in Modular Power Supplies and Their Functions

Date:2025-08-06 Publisher:BettpowerA modular power supply is an electronic device that converts electrical energy into specific voltage and current outputs. It is widely used in industrial control, communication equipment, computer systems, medical instruments, and other fields. To achieve efficient, stable energy conversion and protection functions, modular power supplies typically contain various critical components internally. This article will detail the common core components found in modular power supplies and their respective functions.

I. Main Control Chip (PWM Controller)

The main control chip serves as the core control unit of the modular power supply. It generates pulse width modulation (PWM) signals to control the conduction and switching of power transistors, thereby regulating the output voltage or current. It typically incorporates functions such as overcurrent protection, overvoltage protection, and undervoltage lockout.

II. Power Switching Devices

Power switching devices execute energy conversion within the module power supply, primarily handling high-frequency switching of electrical power. Common types include:

— MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor): Suitable for high-frequency, low-voltage applications with low conduction losses.

— IGBT (Insulated Gate Bipolar Transistor): Suitable for high-voltage, high-current applications, commonly used in DC/AC inverters or high-voltage power modules.

— Bipolar Junction Transistor (BJT): Still employed in some low-cost or low-frequency applications.

III. Transformers and Inductors

1. Transformers

In isolated module power supplies, transformers provide electrical isolation between input and output while converting voltage. By adjusting the turns ratio between primary and secondary windings, they enable step-up or step-down functionality.

2. Inductors

Inductors primarily serve for filtering, energy storage, and suppressing current transients. In non-isolated topologies like Buck and Boost, inductors are critical components for energy storage and output smoothing.

IV. Rectifier and Flyback Diodes

1. Rectifier Diodes

Rectifier diodes convert AC to DC and are commonly found in AC/DC module power supplies. High-speed recovery diodes (SR) and Schottky barrier diodes (SBD) are widely adopted due to their rapid response characteristics.

2. Freewheeling Diodes

In switching power supplies, when the power switch turns off, the current in the inductor requires a freewheeling path. The freewheeling diode provides this path, preventing voltage spikes from damaging the switching devices.

V. Filter Capacitors

Filter capacitors stabilize voltage, absorb ripple and noise, and enhance power supply output quality. Common types include:

— Electrolytic capacitors: High capacitance, low cost, but limited lifespan; suitable for input/output filtering.

— Ceramic Capacitors: Excellent high-frequency performance, used for decoupling and high-frequency filtering.

— Film Capacitors: High voltage rating and stability, commonly used in high-voltage filtering applications.

VI. Optocouplers and Feedback Circuits

Feedback circuits monitor output voltage or current, relaying information to the main control chip to form a closed-loop control system that ensures output stability. Common feedback methods include:

— Optocoupler Isolation Feedback: Uses optocouplers to achieve electrical isolation between input and output, enhancing safety.

— Voltage Reference and Error Amplifier: Such as the TL431, often used for precisely setting feedback voltage thresholds.

VII. Protective Components

To enhance reliability and safety, power modules typically integrate the following protective elements:

— Fuses / Self-Resetting Fuses (PTC): Prevent circuit damage from overcurrent.

— Metal Oxide Varistors (MOV): Absorb surge voltages, protecting against lightning strikes or grid fluctuations.

— TVS (Transient Voltage Suppression Diodes): Provide electrostatic discharge (ESD) protection.

— Temperature Sensor: Monitors module temperature to prevent overheating damage.

VIII. Auxiliary Components

— Heat sinks / Fans: Dissipate heat from power devices to ensure stable long-term operation.

— PCB boards and connectors: Support circuitry and enable internal/external module connections.

— EMI filters: Suppress electromagnetic interference to meet electromagnetic compatibility (EMC) requirements.

The design of modular power supplies involves multiple critical components that work together to achieve efficient energy conversion, stable output, and comprehensive safety protection. With technological advancements, components continue to evolve toward miniaturization, higher efficiency, and greater intelligence, enabling continuous improvements in the performance, reliability, and adaptability of modular power supplies.

Sample

Sample

Tel

Tel

Email

Email

TOP

TOP