What are the common failure modes and how can they be prevented in constant-voltage input DC-DC module power supplies?

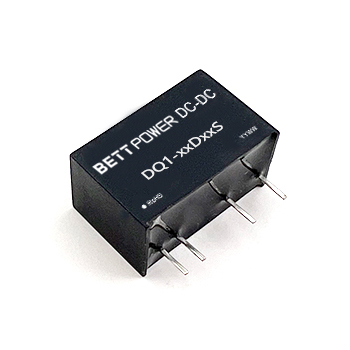

Date:2025-11-09 Publisher:BettpowerIn applications, failure modes of constant-voltage input DC-DC module power supplies (such as Buck, Boost, or non-regulated LDO types) are often related to power device stress, environmental adaptability, and insufficient circuit protection. The following analysis covers failure types, causes, and preventive measures based on scenarios like outdoor charging stations:

I. Common Failure Modes and Causes

1. Overvoltage Breakdown Failure

· Causes:

- Input-side transient overvoltage (e.g., surge, power switching transients) exceeding the module's input withstand voltage (e.g., a rated 24V module subjected to impacts above 36V).

- Reverse voltage generated during capacitive load closure at the output (e.g., back-feeding during large capacitor charging).

- Continuous overvoltage input due to failure of upstream surge protection devices (e.g., MOV short circuit).

· Typical Scenario: After lightning strikes an outdoor charging station, input surges are not fully suppressed, causing internal MOSFET or IC breakdown in the module.

2. Overcurrent Burnout Failure

· Causes:

- Load short circuit or overload (e.g., charging cable insulation failure causing short circuit), with no overcurrent protection or excessively high protection threshold in the module.

- Excessive input inrush current during startup of non-regulated modules (e.g., Buck converters) due to output filter capacitor charging, exceeding the rated current of internal power devices.

- Inadequate thermal management causing heat accumulation during overcurrent, leading to thermal breakdown of components (e.g., current runaway after inductor saturation).

3. Thermal Failure (Overheating Burnout)

· Causes:

- High ambient temperatures in outdoor environments (e.g., case temperatures exceeding 70°C in summer), combined with insufficient module thermal design (e.g., absence of heat sinks, poor thermal conductivity of potting compound).

- Low efficiency of non-regulated modules (e.g., high power dissipation in Buck converters under large input-output voltage differentials), leading to prolonged full-load operation that exceeds maximum junction temperature limits (e.g., MOSFET junction temperature > 150°C).

- Blocked heat dissipation paths (e.g., dust accumulation, cracked potting compound) increasing thermal resistance.

4. Electrolytic Capacitor Aging Failure

· Causes:

- Electrolyte drying in high-temperature environments (e.g., operating temperatures exceeding 85°C shorten lifespan to under 1 year).

- Excessive input voltage ripple causing prolonged exposure to high-frequency ripple currents, leading to increased ESR, overheating, and potential explosion.

· Typical Symptoms: Sudden surge in output voltage ripple; abnormal output voltage establishment during module startup.

5. Mechanical Stress-Induced Failure

· Causes:

- Outdoor vibration (e.g., vehicle docking vibrations at charging stations) causing PCB solder joint cracking and connector loosening.

- Poor potting process in modules; thermal cycling (-40°C to 85°C) causing gel-to-component interface cracking and moisture ingress leading to short circuits.

6. Environmental Failure

· Causes:

- Corrosion of PCB copper traces and oxidation of solder joints in humid/salt-fog environments (e.g., coastal areas).

- Dust/oil accumulation causing poor heat dissipation or tracking short circuits (e.g., unsealed outdoor charging stations).

II. Preventive Measures and Design Optimization

1. Overvoltage Protection Design

· Input-level protection:

- Series TVS (e.g., 1.5kW/36V) or MOV (e.g., 68Vrms) suppress transient overvoltages, ensuring module input withstand voltage ≥ 1.5 times the rated value (e.g., select 40V+ withstand voltage for 24V modules).

- Incorporate overvoltage lockout circuitry (e.g., comparator + MOSFET) to disconnect power when input voltage exceeds threshold, preventing sustained overvoltage.

· Output Protection:

- Parallel Schottky diodes (e.g., MUR1560) to prevent reverse voltage from capacitive loads; diode withstand voltage ≥ 2 times output voltage.

2. Overcurrent and Short-Circuit Protection

· Hardware Current Limiting:

- Series-connect a resettable fuse (PPTC, e.g., 10A/30V) or ceramic fuse (slow-blow type) at the input with a response time ≤10ms.

- Incorporate a current sensing resistor (e.g., 0.01Ω/5W) + comparator in the power path to trigger hiccup protection.

· Module Selection:

- Choose non-regulated modules with built-in current limiting (e.g., select Buck modules where the current limit can be set to 1.2–1.5 times the rated current).

3. Thermal Management and Heat Dissipation Optimization

· Heat Dissipation Design:

- Directly solder heat sinks to the module's metal casing (thermal resistance ≤2℃/W). For outdoor applications, use aluminum extrusion heat sink enclosures with surface area ≥100cm².

- Use thermally conductive silicone rubber (thermal conductivity ≥2W/m・K) during potting to fill gaps between components and casing, eliminating air layers that trap heat.

· Derating Design:

- Calculate junction temperature based on maximum ambient temperature + thermal resistance to ensure MOSFET junction temperature ≤125°C (e.g., at 70°C ambient and 5°C/W thermal resistance, power consumption ≤(125-70)/5=11W).

- Non-regulated modules require derating when input-output voltage difference exceeds 50% of rated value (e.g., 24V input → 12V output power consumption increases by 40% compared to 24V → 20V).

4. Capacitor Selection and Lifespan Optimization

· Capacitor Selection:

- Choose 105°C high-temperature rated input filter capacitors (e.g., Nichicon UHW series), with rated voltage ≥ 1.5 times input voltage (e.g., 47V capacitor for 24V input).

- Parallel high-frequency, low-ESR ceramic capacitors (e.g., 10μF/50V + 100nF/50V) with output capacitors to reduce ripple current impact on electrolytic capacitors.

· Ripple Control:

- Limit input ripple voltage ≤ 5% of rated input (e.g., 24V input ripple ≤ 1.2V), with ripple current ≤ 80% of capacitor rating.

5. Mechanical and Environmental Protection

· Structural Reinforcement:

- Increase pad area for critical PCB solder joints (e.g., power device pins), using wave soldering + adhesive reinforcement to withstand vibration (frequency 10~500Hz, acceleration 50m/s²).

- Use latch-type connectors (e.g., Hirose HR10 series) with potting for waterproofing (IP67 rating).

· Environmental Protection:

- Module housing features IP65 waterproof design with silicone gaskets at seams; internal PCB coated with conformal coating.

- Coastal regions utilize anti-salt spray coatings (e.g., zinc-nickel alloy plating) to prevent metal corrosion.

6. Other Reliability Designs

· EMI Suppression:

- Input-side series common-mode choke (e.g., 220μH) + X capacitor (0.47μF/275VAC) to reduce IC malfunctions caused by switching noise.

· Redundancy Design:

- Parallel identical modules (with current-sharing resistors) in critical applications to maintain system operation during single-module failure.

III. Typical Failure Cases and Solutions

1. Case: Frequent Burnouts of Outdoor Charging Pile Modules in Summer

· Cause: Module lacked heat sinks; summer housing temperature reached 80°C, causing internal MOSFET junction temperatures to exceed 150°C and result in thermal breakdown.

· Solution: Replaced with modules featuring aluminum heat-sink enclosures. Encapsulated with thermal grease (thermal conductivity 3W/m・K) and incorporated heat fins into the enclosure design. Reduced thermal resistance to 3℃/W, maintaining junction temperatures below 120℃.

2. Case: Module fails to restart after output short circuit

· Cause: Lack of overcurrent protection; inductor saturation during short circuit caused sudden current surge, burning out the driver IC.

· Solution: Series a 10A PPTC (e.g., Littelfuse 0898 series) at the input. Limits current within 10ms during short circuit and automatically resets after fault clearance.

Summary

Failure prevention for fixed-voltage input non-regulated DC-DC modules requires addressing three key aspects: “electrical stress control, thermal management, and environmental adaptability.” This involves suppressing transient impacts through multi-level overvoltage/overcurrent protection, optimizing thermal design and derating to control temperatures, and enhancing outdoor environmental resilience through potting, conformal coating, and similar processes. Additionally, component selection must incorporate over 20% parameter margin (e.g., voltage rating, current, temperature), with design validation through reliability testing including vibration and thermal cycling.

Sample

Sample

Tel

Tel

Email

Email

TOP

TOP